Introducing impi! - Pierre Bienvenüe

![]() I'm happy to introduce Pierre Bienvenüe, founder of impi Business Improvement Solutions Pty, a South African business improvement firm and TeamPage solution partner since 2012. Pierre has great experience in helping mid-size companies organize and run effective quality improvement programmes. impi! works with clients as partners from concept definition, initial rollout, through improvement of the quality program itself. Pierre has worked with Traction Software and clients to develop templates, plug-in extensions, and a methodology for using TeamPage to support the impi! business improvement model, with solid results to report. This post is an introduction. You'll hear more from Pierre as an expert guest blogger on this page, in Traction Software's TeamPage customer forums (free registration), and across the web.

I'm happy to introduce Pierre Bienvenüe, founder of impi Business Improvement Solutions Pty, a South African business improvement firm and TeamPage solution partner since 2012. Pierre has great experience in helping mid-size companies organize and run effective quality improvement programmes. impi! works with clients as partners from concept definition, initial rollout, through improvement of the quality program itself. Pierre has worked with Traction Software and clients to develop templates, plug-in extensions, and a methodology for using TeamPage to support the impi! business improvement model, with solid results to report. This post is an introduction. You'll hear more from Pierre as an expert guest blogger on this page, in Traction Software's TeamPage customer forums (free registration), and across the web.

Pierre Bienvenüe writes: Since 2012, the trigger to develop impi! was primarily the realisation that mid-size companies couldn’t afford quality improvement programmes à la TRACC, 20-Keys, Mission Directed Workteam or BMGI offering. Furthermore, they didn’t want an improvement programme but needed a business management system (BMS). Something that would outlive the consultant… (btw they didn't want training either, but coaching.)

Additionally, for a few years now we have experienced the convergence of Quality Assurance and Continuous Improvement. The latter becoming the enabler of the former. Since July 2015, I've had the privilege to contribute to the ISO 9001:2015 implementation at one of my clients (my official guinea pig!) under the guidance of one of the contributors to the new version of the standard. impi! has proven itself to be a solid and flexible platform to work through the implementation and manage the required documentation. As a result, the current impi! solutions are supportive of the new standard.

Why choosing mid-size companies? Their systems are usually less mature than that of large corporations and therefore, the implementation of an IT system underpinning the BMS wouldn’t usually clash with legacy systems. Also, most importantly, top management in mid-size organisations are more likely to get their hands dirty coaching the teams (changing the nappies) rather than the consultant-nanny who too often ends up raising the kids by implementing the programme bottom-up (which always fails in my experience).

A few concepts to build a business management system

impi! is applying the Lean tools and techniques other programmes offer (and probably not as well due to my limited experience and resources to develop the content). However, there are a few concepts, possibly original, that I’d like to share with you:

1. Integration of document management and improvement, blurring the lines between creativity and discipline, short term operation and long term systemic improvement.

The question here is how to ensure that improvement results in standardisation and standardisation in sustainability. There is always a tension between moving fast in improving and taking time to properly document, train and even audit.

Another tension exists between the daily operation (immediate) and its systemic improvement (essential). Here, a footnote on the Toyota Way led me to Paul Adler's article: “Building better bureaucracies” (see also attachment) on enabling vs coercive structures. And gave me hope that discipline and creativity should coexist in the workplace.

My response to the two challenges is:

- A dynamic business model, the Core Cycle, summarised by Drucker definition of management: “the essence of management is to make knowledge productive”. This model helps me to have an integrated view on how a business operates and therefore develop interlocking solutions to build its BMS. I attach a presentation of the Core Cycle, a subset of the foundation course I train my clients with;

- A technology (social media for companies: TeamPage) as an enabler of the Core Cycle that provides an integrated work environment, flexibility, ease of use and at the same time provides structure and visibility. With the technology we can have knowledge workers and even supervisors to collaborate, share, task, project manage, create and manage documents, etc.

I experimented and now understand that the technology - social media for companies (Enterprise 2.0) - and the philosophy - the Toyota half-way (see attachment) - share many principles: collaboration, transparency, accountability, emergence (pattern of improvement: pushing the knowledge threshold by doing).

- Adler - Building Better Bureaucracies

- Bob Emiliani - The Toyota Half-Way

- This presentation is designed for PowerPoint 2010. the core cycle model is animated, so don’t move forward too quickly: Core Cycle slides

2. Management needs to become a routine, implementing a routine is a project, starts at the top, everyone is responsible for improving the organisation. entrench the routine of change before planning to roll out at operational level. Rather than starting an improvement programme - typically with business goal alignment, we first need to build the structure for improvement.

I found that a two-weekly cycle of project review sets up a pace for the company and puts the right pressure on both top management and project leaders. I borrowed that idea from a 6-sigma project management method.

Everyone with a computer runs an improvement project (initially) related to their processes. The project leader gets some face time weekly (20 to 60 minutes) with a sponsor (the process owner = top management). Every two weeks, project leaders stand up and give an account of progress before top management using TeamPage. This is show time. Coaching and learning naturally happens. Con artists are exposed. We get to eat together. We celebrate project closure. The improvement champion (internal or external) can use that time for short training time at the point of need (e.g. what the hell is the Toyota Kata? What is a Pareto analysis, how and when to use it?). The forum is also used to get the teams to contribute to the Long Range Planning process.

Then implementation of any system is pushed through that improvement process. It is logged and managed as a project e.g. establishing standard meetings, rolling out KPIs, ISO 9001 implementation, 5S and of course improvement of business and operational processes. So we guarantee alignment to strategic objectives and make the workload of project leaders obvious.

3. Mirror the social media spaces to the actual Mini Business Units (MBUs). Harmonious mix of electronic and manual visual management

We create spaces for the systemic, strategic and selected operational mini-business units. The more the team uses the platform for its daily operation for communicating and tasking, the easier it becomes to use it for project management and documenting: it is the same platform. A bonus feature is that email traffic diminishes. Visual management (e.g. KPI tracking) is still displayed on the walls, yet in some cases is duplicated electronically. Tasking and minute taking is captured live by the team members in the relevant MBUs. Knowledge can also be created in the context of daily activities with threaded discussions. The discussions are usually informal but they are searchable and can be tasked.

4. Use the BMS to provide knowledge

Sharing of knowledge is woven into the BMS. Firstly, in the central repository of standard documentation (Best Operating Practice - BOP), secondly in the project templates themselves (e.g. DMAIC, Business Process Improvement), thirdly in the MBU spaces as described in Para 3:

- All impi! solutions are built on TeamPage on a wiki space and are standard documents. Every solution starts with a Policy (the why) and a Standard Operating Procedure (the how). The SOP is the hub that links all the other documents (the spokes). The templates used for these documents are the same that the client can use for their own controlled documentation in their own wiki space called “Knowledge Central”. Two outputs of every improvement projects are a) an operational improvement and b) documentation in Knowledge Central. The project templates used to run improvement projects comprise standard articles that will naturally become elements of the BOP (e.g. SIPOC, business process maps). When the project leader reaches the Control or Adjust part of the project, large chunks of the documentation would have been written. Using the capability of TeamPage simplifies the linking and tagging of documents. The organisation steadily builds its very own Wikipedia, and it’s ISO 9001 compliant. The risk of deadwood documentation is reduced: team members create their own documentation, hyperlinking contextualises the documentation and tagging and search capability ease retrieval of information.

- Several templates are available for improvement projects (e.g. PDCA, DMAIC). With each project milestones are associated standard articles e.g. project charter, project checklist, Fishbone diagram, business process “AS IS". To each milestone there are also associated tasks. In each task is a tutorial on its own with tips and links to glossary terms, One Point Lessons (e.g. How to use a risk assessment matrix) or external reference in the public domain, e.g. Wikipedia, Lean Institute.

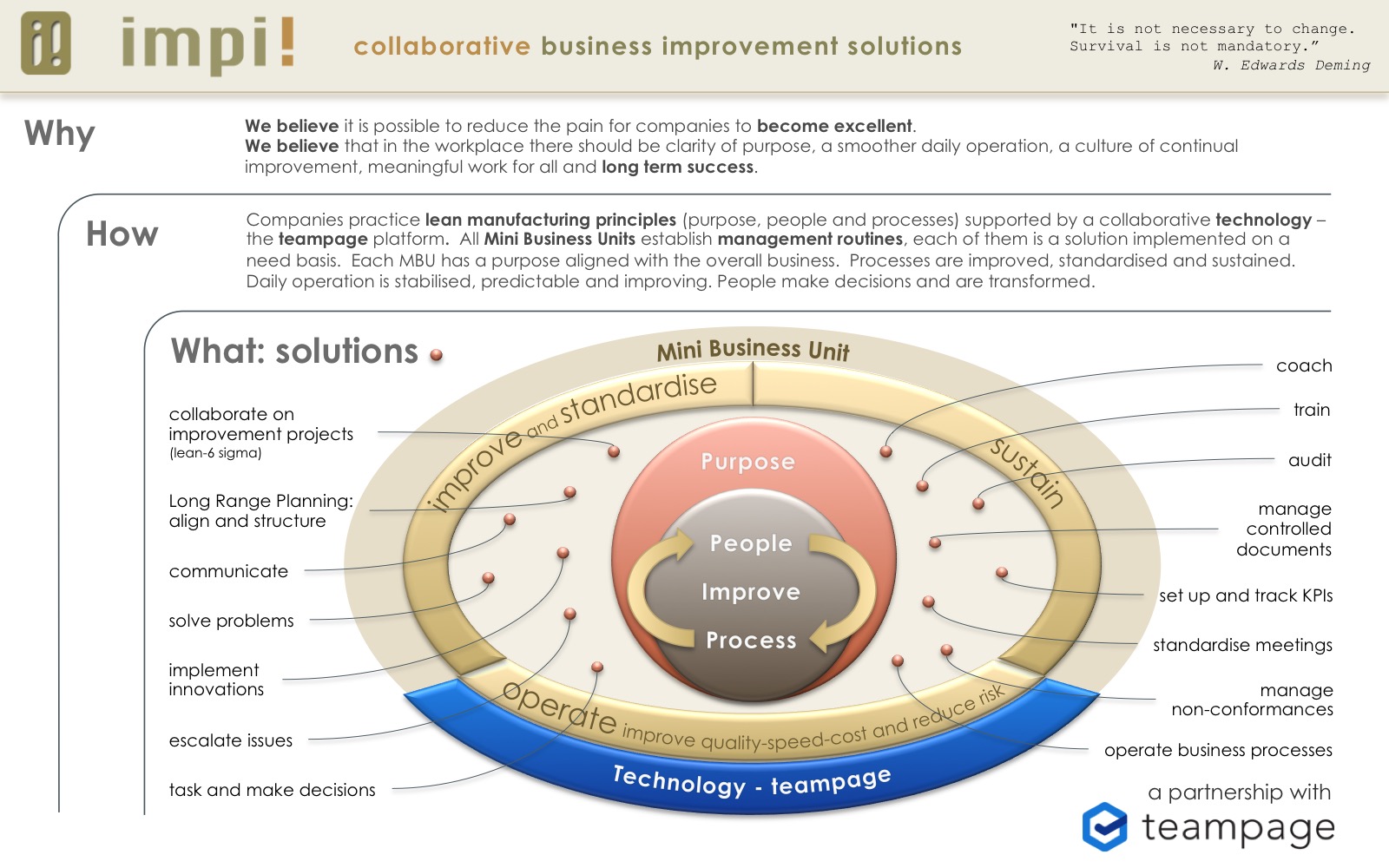

Finally, here is a one page summary of impi! and the synopsis of one of the three solutions that Traction and I have released thus far and are currently being used at clients.

Voilà - I hope there is enough meat here to stimulate a conversation or two.

Since I have only developed impi! thus far with my clients and for my clients, I haven't started a public website. It will be up this year. Immediately though, I will value the comments and interactions @Pierre on Traction Software's TeamPage server (free registration) or email pierre@impi.solutions. In the meantime, gazing a last time at the horizon of this South African part of the Indian Ocean, I'm aiming down to the engine room, pondering how I am to navigate this blue ocean.

Related

Jun 2016 | ISO 9001:2015 Requirements Met By impi! Solutions - Meeting ISO 9001:2015 requirements using the impi! model

impi! What's in the name? What's in the logo? - Discipline and creativity

Dec 2016 | Business Process Improvement with impi!, Plug-in extensions, TeamPage improvements

Why, How and What of the impi Standard Meeting Plug-in for TeamPage - A customer interview and walkthrough of one new part of the impi! BMS solution

I18N ERROR: @tsiskin#footer_RSS_Feed

I18N ERROR: @tsiskin#footer_RSS_Feed